◆Used for disassembly, assembly, cleaning and measurement of rolling bearing in rolling mill.

◆ The original manual operation is now semi mechanized. One working team is reduced from more than 30 people to 8 people. The effect of "one increase and two decrease" is remarkable: work efficiency is greatly improved, labor intensity and production cost are greatly reduced.

◆ Yz130 has been serialized.

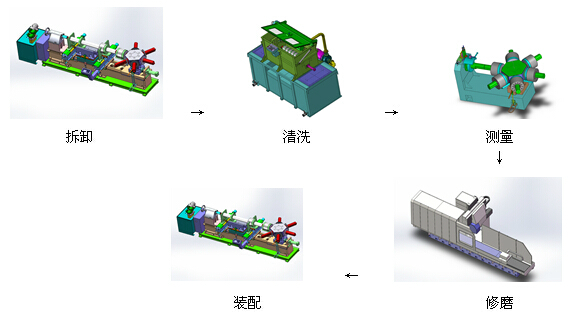

◆ It can be equipped with cleaning machine and measuring machine.

◆ A complete set of production lines can be established, as shown in the figure below.

|

project

|

Specification parameters

|

|

|

YZ130

|

YZ130A

|

YZ130B

|

|

Roll shaft length (mm)

|

1500

|

1800

|

1800

|

|

Roller bearing diameter (mm)

|

300

|

300

|

408

|

|

Inner diameter of roll bearing (mm)

|

130

|

130

|

180

|

|

Rotary shaft taper hole

|

Morse 5

|

Morse 5

|

Morse 5

|

|

Diameter of rotary shaft

|

130

|

130

|

180

|

|

Taper hole of tailstock sleeve

|

Morse 5

|

Morse 5

|

Morse 5

|

|

Diameter of tailstock sleeve

|

90

|

90

|

90

|

|

Tailstock sleeve stroke (mm)

|

235

|

235

|

235

|

|

Self centering jaw stroke (mm)

|

400

|

400

|

500

|

|

Stroke of hexagonal turret (mm)

|

120

|

120

|

120

|

|

V-type auxiliary positioning lifting table

Stroke (mm)

|

130

|

130

|

130

|

|

Hydraulic motor power (kw)

|

3

|

3

|

3

|

|

Overall dimension of disassembly machine (L) × w × h) (cm)

|

450×180×220

|

450×180×220

|

550×180×220

|

|

Disassembling machine mass (kg)

|

5000

|

5000

|

6000

|